Introduction of Lean Industry 4.0

Industry 4.0 can bring a lot of improvements by itself, all other things

being equal, but without the synergy through the.combination of Lean, the full benefits will not be reaped.

The combination of Lean and Industry 4.0 is then called Lean 4.0.Lean and Industry 4.0 philosophies are often complementary

and can give manufacturing or operations managers insight into achieving a higher level of production efficiency.

Boston Consulting Group says manufacturers who have successfully deployed both ideas have reduced conversion costs by as much as 40 per cent in five to 10 years; a better result than deploying either of the philosophies individually. But the concept is new, with fewer than five per cent of manufacturers reaching a high level of maturity in Lean Industry 4.0.

Boston Consulting Group says manufacturers who have successfully deployed both ideas have reduced conversion costs by as much as 40 per cent in five to 10 years; a better result than deploying either of the philosophies individually. But the concept is new, with fewer than five per cent of manufacturers reaching a high level of maturity in Lean Industry 4.0.

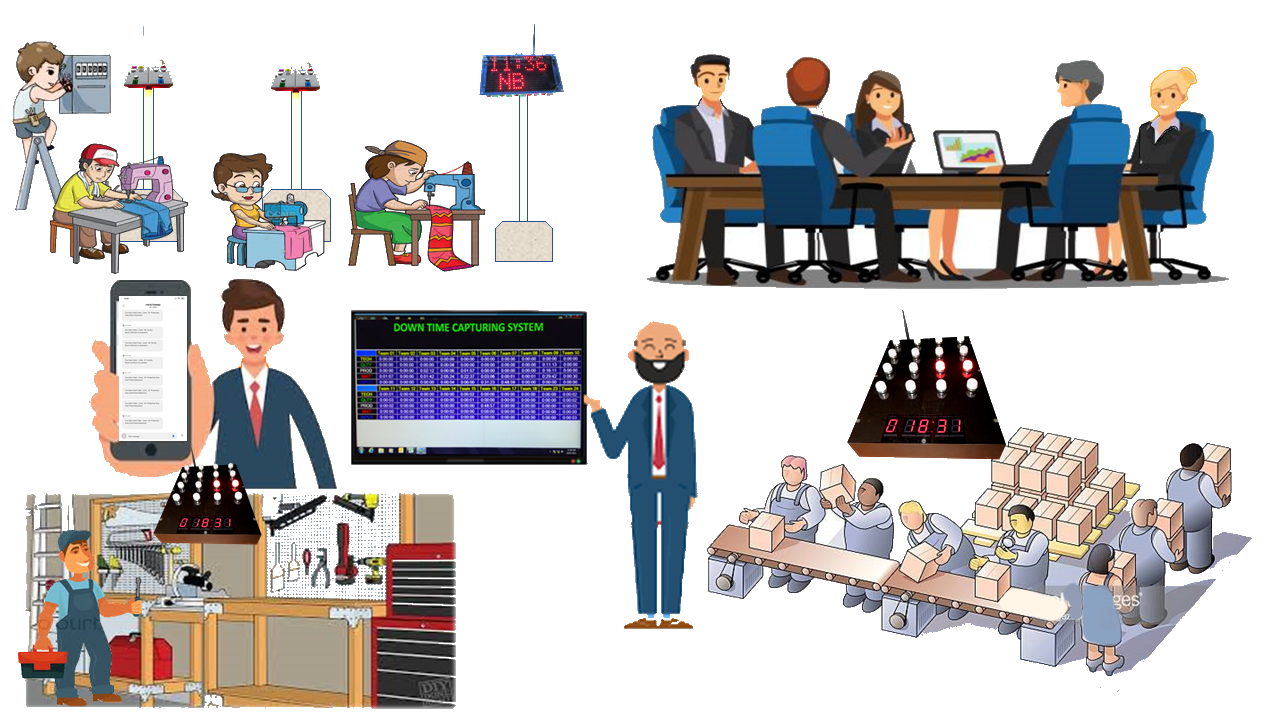

➢ "What is Andon System?"

In lean Manufacturing, the term Andon is a system that notifies employees if production processes are

interrupted.This can include quality issues, machine interruptions, missing material or any other processing problem. Andon alert are usually

issued manually by operators pulling a so called Andon cord or by pushing an Andon button. Andony systems can connected directly to

machines or equipment and can then be activated automatically by the machines itself.

The target of Andon systems is to pause production when a defect is found and call for assistance to take corrective actions.Most Andon systems use audio alarms, text and display messages on Andon boards, very often stack lights are used to visually indicate status changes. Common reasons to trigger Andons are missing parts, malfunctions of tools, identified defects, scrap or other quality issues and potential safety problems.

The target of Andon systems is to pause production when a defect is found and call for assistance to take corrective actions.Most Andon systems use audio alarms, text and display messages on Andon boards, very often stack lights are used to visually indicate status changes. Common reasons to trigger Andons are missing parts, malfunctions of tools, identified defects, scrap or other quality issues and potential safety problems.

➢ What are the Andon System benefits.

• Greater productivity and better management of resources.

• More efficient decision-making based on real information.

• Optimized and integrated productive processes Increase the flexibility to achieve a mass production and personalized in real time.

• Direct communication between clients and organizations, which means that we can better understand what customers need.

• Reduction of manufacturing time both in the design of new products and in the merchandising of these.

• Reduced costs and downtime

• Enhanced value to the customer because of better quality products

• Responsible operators who are accountable for the line running as efficiently and effectively as possible, empowering them to act when problems arise, rather than waiting for management

• Long term improvements to production process

• Like most principles in Lean manufacturing, the Andon cord itself doesn’t add value. Likewise, if action isn’t taken immediately when the system is alerted, it defeats the purpose and can actually detract from the value you are targeting.

• More efficient decision-making based on real information.

• Optimized and integrated productive processes Increase the flexibility to achieve a mass production and personalized in real time.

• Direct communication between clients and organizations, which means that we can better understand what customers need.

• Reduction of manufacturing time both in the design of new products and in the merchandising of these.

• Reduced costs and downtime

• Enhanced value to the customer because of better quality products

• Responsible operators who are accountable for the line running as efficiently and effectively as possible, empowering them to act when problems arise, rather than waiting for management

• Long term improvements to production process

• Like most principles in Lean manufacturing, the Andon cord itself doesn’t add value. Likewise, if action isn’t taken immediately when the system is alerted, it defeats the purpose and can actually detract from the value you are targeting.

Copyright © 2020 - All Rights Reserved -

Copyright © 2020 - All Rights Reserved -